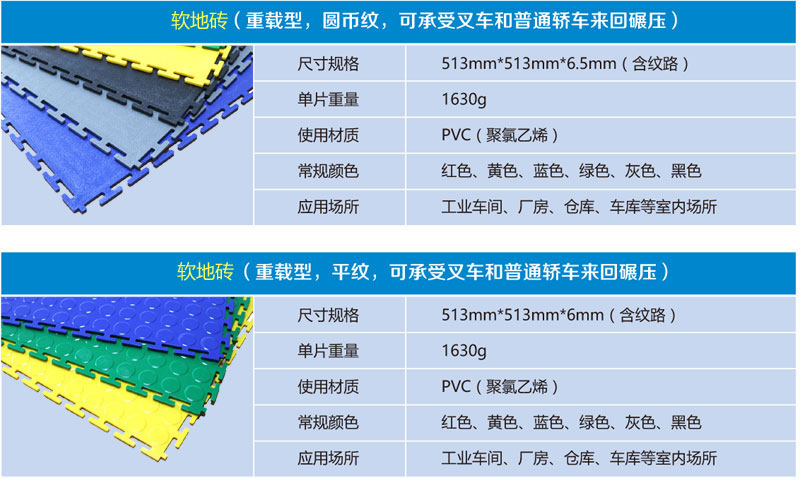

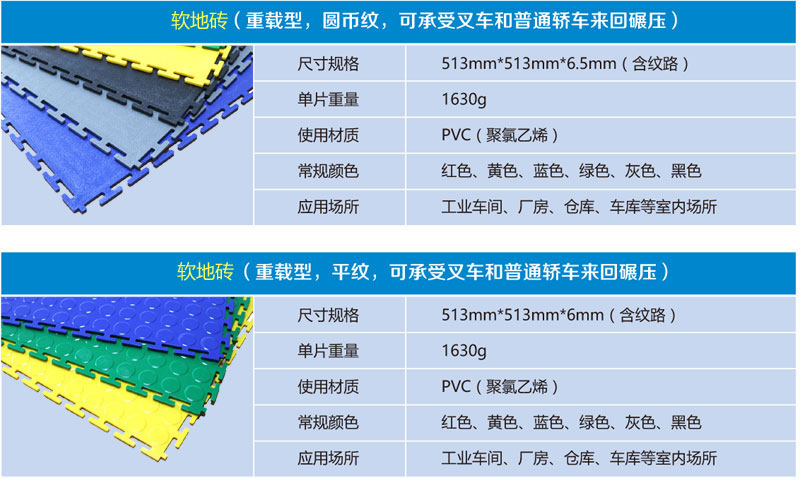

Pvc floor mats use soft polymer plastic materials (polyvinyl chloride), which feature waterproof, oil resistance, non-slip, sound insulation, heat insulation, high load, etc. It can be installed on any of the existing ground foundations including wood, concrete, epoxy coating, ceramic tiles, terrazzo and marble, etc. They are widely used in workshop, warehouse, garage ground , gymnasium, hall and other places.

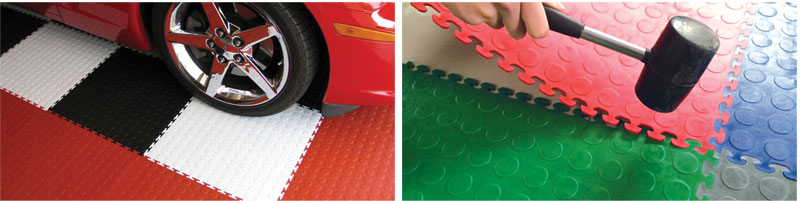

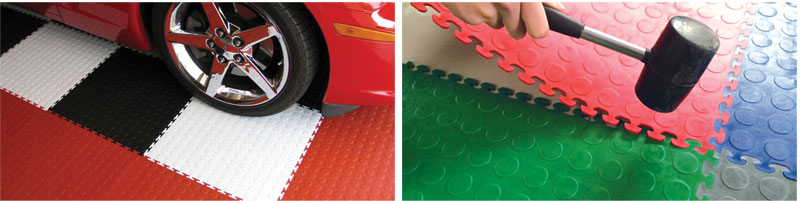

The pvc floor mat can be quickly assembled floor tiles of each individual into a whole ground, patented locking structure has strong connection ability, can withstand the truck rolling back and forth. In the construction process without adhesive material, they have the advantages of simple construction, fast, colorful, beautiful appearance, strong mobility and reusable characteristics.

The pvc foor mats can make each individual mat quickly connect into a whole ground, patented locking structure has stronger connection ability, can withstand the truck rolling back and forth. No glue needed in the construction process. They are simple & fast construction, colorful, beautiful appearance, strong mobility and reusable.

Soft floor tiles with 100% pure new PVC environmental protection raw material production, can be quickly installed on any existing substrate, especially the ground to excessive wear, paint delamination, dust, moisture and contamination, etc., can not affect the rapid escalation of the implementation of the ground under the condition of the normal production workshop.

Product advantages

Oil resistant, good cleaning: pvc floor mat material has a very dense structure, the oil can not penetrate, as long as the oil dripping is removed in time, we can keep the floor clean. Local oil can be directly wiped with a rag, a large area of stains can be cleaned by vacuum cleaner, mop or broom.

Anti impact, easy to maintain: PVC floor mat use soft PVC material, can effectively buffer the impact of the weight of the power, to avoid damage to the ground. The unique structure of the lock also let the floor replacement is very simple, if sharp objects drop on the floor and damage local part, only replace damage location.

Super wear-resistant, long life: PVC floor mats use the thickening production process, the overall thickness of the floor is the overall thickness of the wear-resistant layer, has a super wear-resistant effect. If used in the workshop,the normall service life is 8 - 5 years.

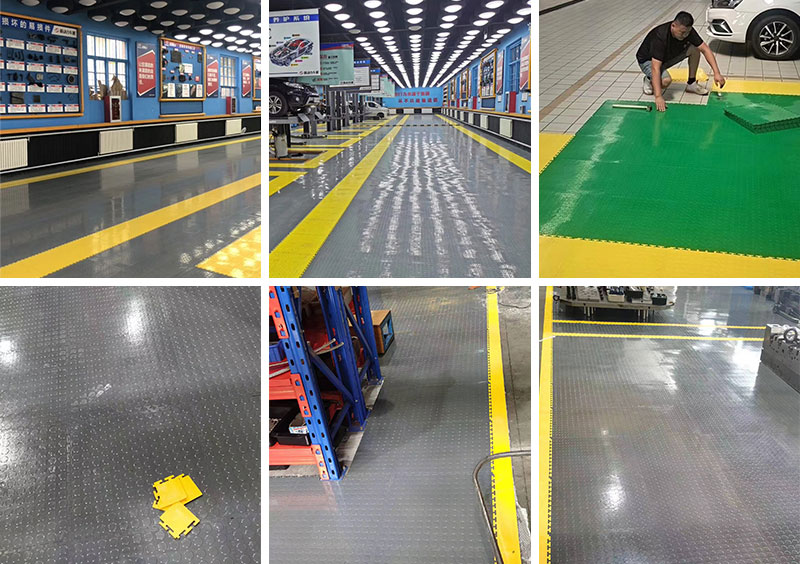

Construction is fast, do not close down: PVC floor mats have low ground requirement, flat and cleaning ground will be ok. No glue needed in the process of construction,connect to the whole ground by interlocking . After laying the products do not need to wait, you can immediately use.

High load, more non slip: PVC floor mat is the solid structure, as long as the ground bearing is no problem, its carrying capacity can reach 10 tons per square meter or more. Floor surface in the production process with raised lines, so that the workshop floor is more non slip.

Bright color, easy Collocation: Regular color is red ,yellow , black, gray, blue and green, color can also be customized according to the customer requirement. The construction is very simple because of square structure.

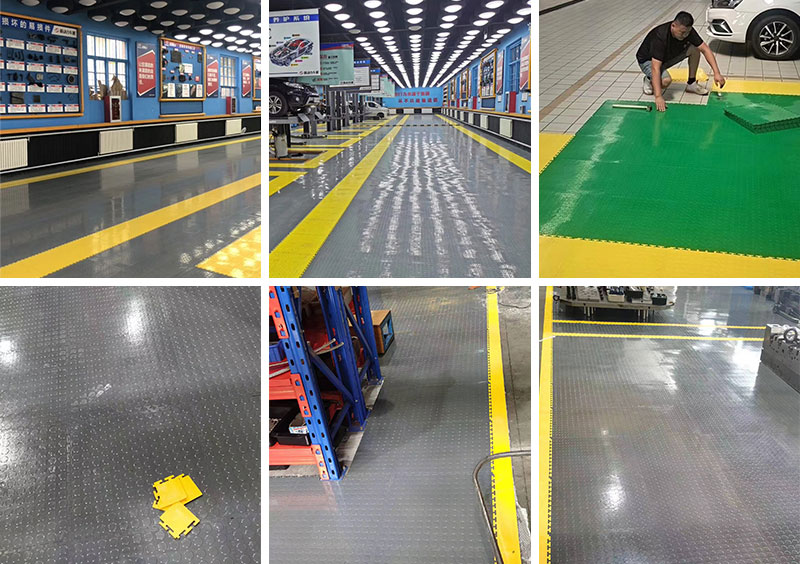

installation case

|